Table of Contents

ToggleUnderstanding The Automotive Digital Revolution

The automotive industry is experiencing a significant shift. This digital transformation is as impactful as the assembly line’s introduction, redefining how vehicles are designed, built, sold, and used. It’s not just about adding fancy touchscreens or driver-assistance features; it’s a complete overhaul. This revolution affects every part of the automotive world, from the factory to the consumer.

Drivers of Automotive Digital Transformation

Several key forces are pushing this digital transformation forward. Consumer desires are changing quickly, with increasing demand for connection, personalized experiences, and environmentally friendly vehicles.

Regulations related to emissions and safety are also playing a major role. Automakers are forced to innovate and adapt to meet these standards.

New digitally focused competitors are also disrupting the market. This pushes established companies to embrace technology in order to stay competitive and relevant. This means prioritizing digital strategies is no longer optional, it’s essential for survival.

The worldwide automotive industry is also seeing shifts in consumer behavior and technological progress. This adds to the need for businesses to adapt and embrace change. Companies must enhance the buying process through online platforms and use data analytics to boost production. Global vehicle sales are expected to have exceeded 92 million units by the end of 2024. More statistics are available here: 50 Automotive Statistics.

Core Components of the Digital Shift

This transformation involves several core elements. Electrification is a primary factor, affecting not just engines but also how cars are made and the supporting infrastructure.

The growing use of software and data analytics turns cars into smart, connected platforms. These vehicles can offer autonomous driving, predict maintenance needs, and provide custom user experiences. Software is no longer just a supplementary feature; it’s a core component of the modern vehicle.

Impacts of Digital Transformation on the Automotive Industry

The effect of this digital shift is widespread. Smart manufacturing, including robotics and automation, is improving production and efficiency in factories. The customer experience is also changing dramatically, with online car configurators, digital showrooms, and tailored after-sales service. For additional insights on industry trends, see Automotive Trends. This transformation presents both difficulties and exciting possibilities for the car industry.

Navigating the Digital Future

Successfully handling this transformation requires a strategic roadmap. Car manufacturers must invest in technology, build digital skills in their workforce, and encourage a culture of innovation.

They also need to create strong digital networks. This means working with tech companies and startups to gain specialized knowledge and speed up their digital journey. This collaboration is critical for staying ahead in this constantly evolving market. The future of the automotive industry is undoubtedly digital.

Electrification As The Core Transformation Driver

Electric vehicles (EVs) are the most prominent symbol of the automotive industry’s ongoing transformation. But the impact of electrification goes far beyond simply replacing gasoline engines with batteries. It’s fundamentally changing business models, supply chains, and customer interactions throughout the automotive world. This creates both significant challenges and exciting new opportunities.

Reshaping the Automotive Landscape

The increasing popularity of EVs is changing the competitive dynamics within the auto industry. Established automakers are investing heavily in EV technology, while new companies are emerging, focusing entirely on electric powertrains. This competition is driving innovation and accelerating the development of new EV models, batteries, and charging infrastructure. This rapid pace requires all industry players to adapt quickly to avoid being left behind.

This automotive transformation is significantly driven by electrification and software integration. Gartner predicts a 17% increase in EV shipments by 2025, with over 50% of all vehicle models projected to be electric by 2030. This shift is more than just electrification; it includes integrating software to enhance performance and the overall user experience. For a deeper dive into these trends, check out Gartner’s Key Automotive Trends.

Software’s Crucial Role in Electrification

Software integration is essential for the success of EVs. Advanced software manages battery performance, optimizes power delivery, and gives drivers real-time information about range and charging status. Furthermore, software updates can be delivered remotely (over-the-air updates), improving vehicle functionality and performance throughout its lifespan. Software is now a crucial part of the EV ownership experience.

Beyond these essential functions, software plays a key role in crafting unique user experiences. Features like personalized driving profiles, advanced driver-assistance systems (ADAS), and seamless integration with mobile devices are becoming standard. This level of software integration blurs the lines between the automotive and technology sectors, pushing automakers to embrace new development processes.

Infrastructure Challenges and Opportunities

Widespread EV adoption hinges on developing a reliable charging infrastructure. The availability of public charging stations, access to fast-charging options, and integration with smart grids are critical for addressing range anxiety and making EVs a practical choice for consumers. While this presents some hurdles, it also creates opportunities for companies offering innovative charging solutions.

For additional insights on marketing in the automotive sector, see How to Master Automotive Marketing.

Regulatory Landscape and its Influence

Government regulations and incentives heavily influence EV adoption. Emissions standards, tax credits, and subsidies can incentivize consumers to buy EVs and encourage automakers to invest in their development. However, these policies can also create complexities and uncertainty for businesses, requiring careful planning and adaptation. For instance, different regulations across various regions can challenge companies operating internationally.

Strategies for an Electric Future

Successfully transitioning to an electric future demands a multi-pronged strategy. Automakers must invest in research and development, collaborate with technology companies, and adapt their manufacturing processes. Understanding consumer preferences and addressing concerns about charging infrastructure is crucial for building market confidence and promoting EV adoption. This comprehensive approach is the key to realizing the full potential of electrification.

AI and IoT Revolutionizing Vehicle Intelligence

The automotive industry is experiencing a major shift. At the forefront of this change are Artificial Intelligence (AI) and the Internet of Things (IoT). These technologies are transforming vehicles from basic machines into complex, connected systems. These systems can learn, adapt, and communicate with their surroundings and drivers in innovative ways.

Autonomous Driving and Advanced Driver-Assistance Systems

A primary application of AI and IoT is the development of autonomous driving systems. These systems utilize sensors, cameras, and advanced algorithms to navigate roads and make real-time decisions. They can even park automatically. This technology has the potential to significantly improve road safety by reducing human error, a key factor in accidents.

Autonomous vehicles can also optimize fuel consumption and lessen traffic congestion through coordinated driving. AI and IoT are crucial in developing Advanced Driver-Assistance Systems (ADAS). Features like adaptive cruise control, lane keeping assist, and automatic emergency braking depend on these technologies to enhance driver safety and convenience.

These systems are continually evolving, each step bringing us closer to fully autonomous vehicles. Automakers like General Motors and Ford are partnering with tech companies on self-driving car development. These vehicles use real-time data for decision-making, enhancing safety and fuel efficiency. Government support, through incentives and R&D funding, further propels these technologies, especially in autonomous driving and green initiatives like electric vehicles. Learn more about future automotive technology at ilia.digital.

Predictive Maintenance and Enhanced Reliability

Beyond autonomous driving, AI and IoT are changing vehicle maintenance. Predictive maintenance, powered by these technologies, anticipates problems before they occur. By examining data from various vehicle sensors, AI algorithms identify anomalies and forecast part failures.

This enables proactive maintenance, reducing downtime and repair expenses. This proactive method contrasts with traditional reactive maintenance. It increases vehicle reliability and extends its lifespan.

The Data Ecosystem: Fueling Vehicle Intelligence

The effectiveness of these AI and IoT systems relies on a robust data ecosystem. Vehicles utilize a network of sensors collecting diverse data, from engine performance and tire pressure to driver behavior and environmental factors. This information is then sent to a central platform for processing and analysis.

The insights derived from this data improve vehicle performance, personalize the driving experience, and facilitate the development of new automotive services.

Challenges of Integration and Implementation

While promising, integrating AI and IoT into vehicles presents significant hurdles. System reliability and safety are paramount. Automakers must heavily invest in rigorous testing and validation processes to ensure these systems operate correctly under all conditions.

Cybersecurity is a critical concern. Connected vehicles are vulnerable to hacking and data breaches. Protecting vehicle systems and information from cyber threats is a continuous challenge requiring constant attention. Addressing these challenges is essential for the widespread adoption of these transformative technologies.

Smart Manufacturing Revolution On The Factory Floor

The automotive factory floor is transforming. Manufacturers are embracing Industry 4.0 principles to optimize production. This transcends basic automation. It’s about refining every stage of manufacturing. Leading automakers are implementing robotics, machine learning algorithms, and digital twin technology. Their goal? Unprecedented operational efficiency. Let’s explore the key elements driving this smart manufacturing revolution.

Data Analytics: Optimizing Supply Chain Management

Data analytics plays a crucial role in reshaping automotive supply chains. It empowers just-in-time production and minimizes waste. By examining real-time data from across the supply chain, manufacturers gain valuable insights. They can identify potential bottlenecks, fine-tune inventory levels, and enhance logistics.

Predictive analytics, for example, can anticipate demand fluctuations. This ensures the right parts are available at the right time. Data-driven decision-making is a fundamental aspect of automotive transformation. It allows companies to be more proactive and efficient.

Retrofitting vs. Building New: Making Strategic Choices

Automakers face a significant decision: retrofit existing factories or build new smart factories? Retrofitting may offer a quicker, less expensive way to implement some digital technologies. However, legacy systems can create limitations. Building a new smart factory provides a fresh start. It allows for incorporating the latest technologies and optimizing processes from the ground up. But, it involves higher initial costs and longer lead times. The best approach depends on the automaker’s specific needs and resources. There’s no single solution in this complex environment.

Integrating Legacy Systems: Overcoming the Hurdles

Integrating legacy systems with new technologies is a major challenge. Many factories rely on older systems incompatible with modern software and data analytics platforms. This can create data silos. It disrupts the smooth flow of information essential for smart manufacturing. Overcoming this challenge often requires significant investment in system upgrades and integration solutions. This integration is key to unlocking the full potential of Industry 4.0 technologies.

Workforce Transformation: Equipping for the Future

Smart manufacturing demands a skilled workforce. Operating and maintaining advanced robotics, AI-powered systems, and digital technologies requires new expertise. Automakers are investing in training programs. These programs upskill their current workforce and attract new talent with the required digital competencies.

This workforce transformation is crucial for successfully implementing and running smart factories. It requires a commitment to continuous learning and adaptation in this evolving landscape.

Measuring ROI and Managing the Shift

Measuring the return on investment (ROI) in smart manufacturing is essential. It demonstrates the value of these initiatives. Trackable metrics show the benefits. These include increased production output, reduced waste, and improved quality control. Managing the transition to smart manufacturing requires careful planning, open communication, and a phased approach. This minimizes disruption and maximizes the adoption of new technologies. These strategies are vital for long-term success in the evolving automotive industry. This isn’t a one-time project, but a continuous journey of improvement and adaptation.

To further understand the technologies involved, let’s look at a comparison table:

To help illustrate the various technologies used in digital manufacturing, the following table provides a comparison of their applications, benefits, and implementation challenges.

Digital Manufacturing Technologies Comparison

Comparison of key digital technologies used in automotive manufacturing, their applications, benefits, and implementation complexity

| Technology | Primary Application | Key Benefits | Implementation Complexity | ROI Timeline |

|---|---|---|---|---|

| Robotics | Assembly, Painting, Welding | Increased speed, precision, and consistency | Moderate to High (depending on integration with existing systems) | 1-3 years |

| Machine Learning | Predictive Maintenance, Quality Control | Reduced downtime, improved product quality | High (requires data infrastructure and skilled personnel) | 2-5 years |

| Digital Twin | Simulation, Process Optimization | Reduced development time, optimized production processes | High (requires complex modeling and data integration) | 3-7 years |

| Additive Manufacturing (3D Printing) | Prototyping, Customized Parts | Faster prototyping, on-demand manufacturing | Moderate (requires specialized equipment and materials) | 1-2 years |

| Industrial Internet of Things (IIoT) | Real-time data collection and analysis | Improved visibility into production processes, enhanced decision-making | Moderate to High (depending on the scale of deployment) | 2-4 years |

This table highlights the various technologies used in digital manufacturing, ranging from established applications like robotics to more complex implementations like digital twins. The ROI timeline varies depending on the specific technology and the complexity of its integration into existing systems. Choosing the right mix of technologies for a particular manufacturing setting is crucial for maximizing efficiency and achieving desired outcomes.

Transforming Customer Experience Beyond Expectations

The automotive industry is undergoing a significant shift in how customers interact with brands. From initial research to ongoing ownership, every touchpoint is being redefined. This presents a unique opportunity for automakers to cultivate stronger customer relationships, leading to increased loyalty and profitability.

The Rise of Omnichannel Experiences

Leading automakers are prioritizing omnichannel experiences, seamlessly blending online and offline interactions. Customers can begin their journey online, configuring their dream car and exploring financing options through platforms like Dealertrack. They can then transition to a physical dealership for a test drive and finalize the purchase.

This hybrid approach caters to individual preferences, providing flexibility and convenience. The result is a more personalized and satisfying buying process.

For example, a customer researching a car online can save their preferred configuration and schedule a test drive at a local dealership. Upon arrival, the salesperson is prepared with the customer’s information and the selected vehicle. This seamless integration of online and offline touchpoints is the essence of the omnichannel strategy.

Personalization Through Data Analytics

Data analytics plays a crucial role in personalizing the customer experience. By analyzing customer preferences, driving habits, and service history, automakers can tailor interactions. This includes targeted marketing campaigns, personalized vehicle recommendations, and proactive service reminders. You might be interested in: How to Master Automotive Digital Marketing. This personalized approach strengthens customer relationships and encourages repeat business, setting brands apart in a competitive market.

Digital showrooms and virtual reality are further enriching the customer experience. These technologies allow customers to explore vehicles from home, inspecting details and even taking virtual test drives. This expands the reach of dealerships and provides a more convenient and engaging shopping experience, minimizing geographical barriers.

The Evolving Dealership Relationship

Direct-to-consumer (D2C) models are transforming traditional dealership relationships. Some automakers are establishing online sales platforms, enabling customers to purchase vehicles directly. This can simplify the buying process and give customers greater control.

However, this shift also presents challenges for existing dealerships. Automakers must carefully manage this transition to maintain balance between online and offline channels, benefiting both their business and customers.

Subscription-based services, offering access to a vehicle for a recurring fee that includes insurance and maintenance, are also gaining popularity. This alternative to ownership appeals to younger demographics and those prioritizing flexibility. It also represents a fundamental change in automaker revenue generation.

Research analyzing 2,500 automotive customer interactions reveals that omnichannel digital experiences lead to 73% higher customer satisfaction and 2.4 times higher customer lifetime value compared to traditional methods. Learn more about this study here. This data underscores the significant impact of digital transformation on customer satisfaction and business outcomes.

Connected Vehicles and Ongoing Engagement

Connected vehicles and over-the-air (OTA) updates extend customer engagement. Connected cars transmit data on vehicle performance and diagnostics, enabling predictive maintenance and personalized in-car experiences. OTA updates allow automakers to deliver software upgrades and features directly to vehicles, keeping cars up-to-date and enhancing functionality. This fosters a continuous relationship between the automaker and the customer that lasts far beyond the initial purchase.

Measuring Success and Building Loyalty

Measuring customer satisfaction is crucial in the digital age. Tools like customer surveys, online reviews, and social media monitoring provide valuable feedback. This information helps automakers understand customer needs and identify areas for improvement. This feedback informs product development, service enhancements, and refines the customer journey.

Building customer loyalty programs is also essential. These programs offer exclusive benefits and rewards, promoting repeat business and fostering a sense of community among car owners. These strategies, combined with digital tools, are transforming the automotive customer experience, creating more personalized, engaging, and rewarding interactions for both customers and automakers.

Overcoming Digital Transformation Roadblocks

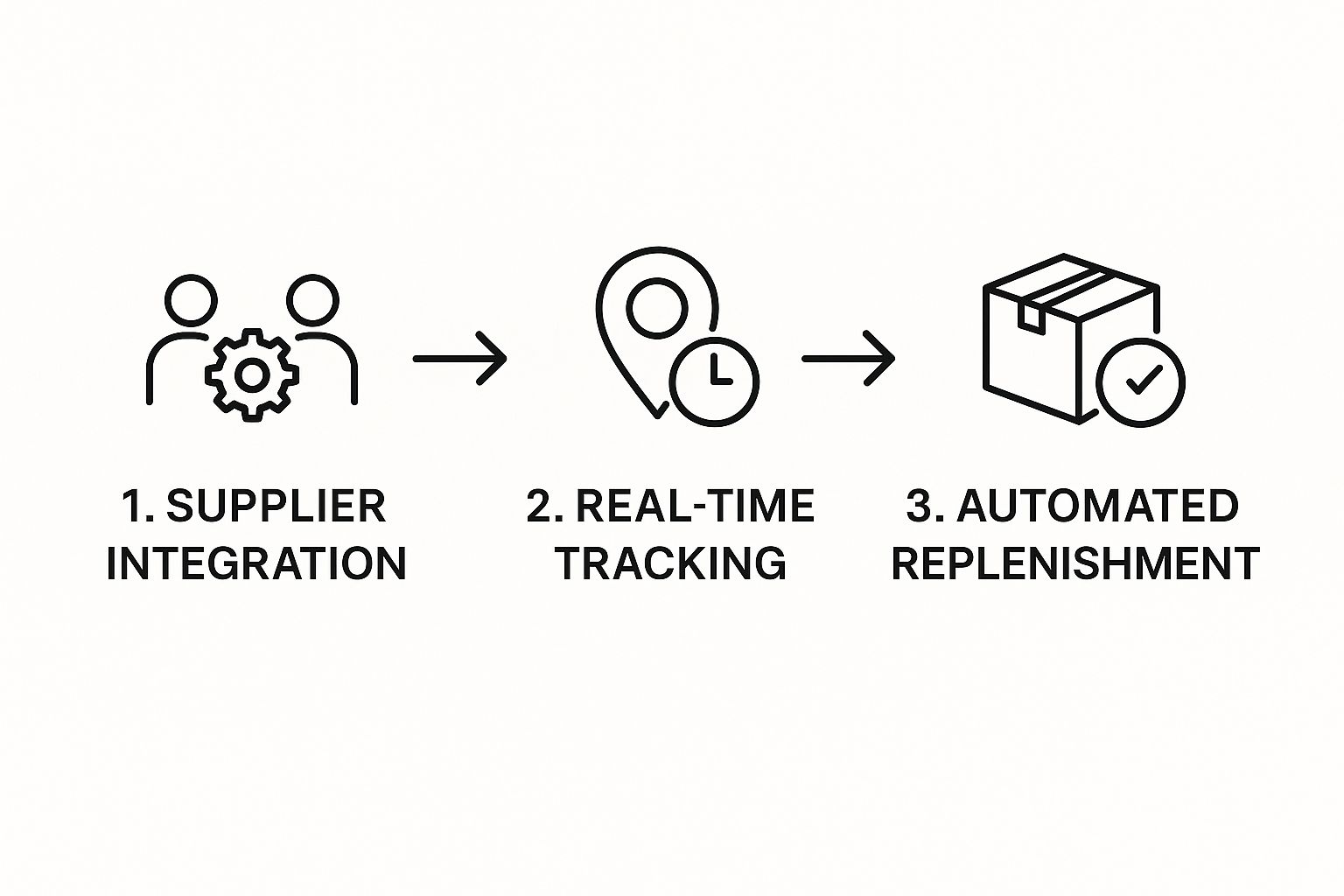

This infographic visually represents the journey of information and materials within a digitally transformed automotive supply chain. It showcases the progression from Supplier Integration to Real-Time Tracking, culminating in Automated Replenishment. This interconnected approach offers significant advantages over traditional methods in terms of efficiency and responsiveness. By linking these critical stages, automakers can optimize inventory levels, minimize delays, and ultimately enhance their overall production efficiency.

Connecting these stages creates a powerful synergy. It simplifies communication and streamlines processes, contributing to a more agile and responsive supply chain. This visualization clearly demonstrates how digital tools can simplify traditionally complex operations.

Legacy Systems and Cybersecurity: Addressing Critical Concerns

Integrating older systems with newer technologies presents a major hurdle in digital transformation. Many factories depend on legacy systems that may not be compatible with modern software and data platforms. This incompatibility can lead to data silos, which disrupt the seamless flow of information vital for effective operation.

Often, investment in system upgrades and integration solutions becomes necessary. This investment can be substantial, but it’s a crucial step in achieving true digital transformation. Moreover, increased connectivity brings a heightened risk of cyberattacks.

Robust cybersecurity measures are therefore paramount. Protecting vehicle systems and sensitive data requires continuous vigilance and investment in security infrastructure. This includes robust firewalls, intrusion detection systems, and regular security audits.

Workforce Transformation: Bridging the Skills Gap

Transitioning to a digitally driven environment requires a skilled workforce capable of operating and maintaining new technologies. Traditional automotive engineering expertise needs to incorporate software-centric development skills. This evolution necessitates both training existing employees and attracting new talent with relevant digital competencies.

Upskilling the existing workforce is essential for a smooth transition. Providing employees with the necessary training ensures they can effectively utilize new technologies and contribute to the transformed environment. Attracting new talent with specialized skills is also crucial.

Furthermore, fostering a culture that embraces change and promotes continuous learning is paramount. This creates an environment where employees are empowered to adapt and thrive amidst the evolving automotive landscape. This includes providing opportunities for professional development and encouraging a growth mindset.

Build vs. Buy: Making Strategic Technology Decisions

Companies face a crucial decision regarding technology implementation: building in-house solutions or buying existing ones. Developing custom solutions, often referred to as the build approach, offers greater control and the potential for competitive advantages. However, this can be an expensive and time-consuming process.

Purchasing existing solutions, known as the buy approach, may be faster and more cost-effective. However, off-the-shelf solutions may not fully address a company’s specific needs. Carefully evaluating these trade-offs is vital.

Making strategic decisions regarding this build-versus-buy dilemma is critical. The optimal approach depends on a company’s available resources, technical expertise, and overall strategic objectives. This decision requires a thorough assessment of internal capabilities and long-term goals.

Partnerships and Ecosystem Development: Accelerating Transformation

Developing strategic partnerships and cultivating a robust ecosystem is vital for overcoming resource limitations. This collaborative approach also accelerates implementation timelines. Collaboration with technology companies, startups, and even competitors can provide access to specialized expertise and valuable resources.

For instance, partnering with software companies like Microsoft can accelerate the development of autonomous driving systems or connected car platforms. Sharing resources and expertise allows companies to distribute the costs and risks inherent in digital transformation.

This shared responsibility fosters innovation and accelerates the development process. Collaborations also provide access to a broader range of perspectives and technologies, enriching the overall outcome. For additional insights, see How to Master Automotive Lead Generation.

Risk Management: Navigating Uncertainty

Automotive digital transformation inherently involves risks. Market fluctuations, technological disruptions, and cybersecurity threats can impede even the most well-planned initiatives. Implementing a comprehensive risk management framework is therefore crucial.

This framework should identify potential risks, assess their possible impact, and develop appropriate mitigation strategies. Regularly reviewing and updating the framework ensures the organization is prepared for unanticipated challenges. This proactive approach helps maintain momentum and minimizes disruptions during complex transformation initiatives.

By proactively addressing potential roadblocks, automotive companies can confidently navigate the complexities of digital transformation and unlock its full potential. A robust risk management strategy empowers organizations to adapt to change and mitigate potential setbacks, ensuring a smoother and more successful transformation journey.

To help visualize the entire digital transformation process, let’s review a sample implementation roadmap.

A Digital Transformation Implementation Roadmap provides a structured approach to managing the complex process of digital transformation. The following table outlines key phases, durations, activities, metrics, and investment levels involved in a typical transformation journey.

| Phase | Duration | Key Activities | Success Metrics | Investment Level |

|---|---|---|---|---|

| Assessment & Planning | 3-6 Months | Evaluate current state, define goals, develop strategy, secure executive buy-in | Clearly defined objectives, stakeholder alignment, documented roadmap | Moderate |

| Pilot Projects | 6-12 Months | Implement small-scale projects to test new technologies and processes, gather data, and refine approach | Proven technology effectiveness, process improvements, data-driven insights | Moderate |

| Implementation & Rollout | 12-24 Months | Deploy new technologies and processes across the organization, provide training and support to employees | Adoption rates, system performance, user satisfaction, ROI | High |

| Optimization & Continuous Improvement | Ongoing | Monitor performance, gather feedback, identify areas for improvement, refine processes and technologies | Improved efficiency, cost savings, increased revenue, enhanced customer experience | Variable |

This roadmap provides a general framework. Specific timelines and activities will vary depending on the individual organization and the scope of its transformation initiatives. Regularly reviewing and updating the roadmap is essential to ensure it remains aligned with evolving business needs and market dynamics.

Key Takeaways

The automotive industry is experiencing a significant digital transformation, affecting every aspect of the business, from manufacturing to customer interactions. This shift presents both challenges and opportunities for growth and innovation. This section highlights key insights for navigating this evolving landscape and achieving digital success.

Embracing Data-Driven Decisions

Data analytics is now essential for intelligent decisions across the automotive value chain. From optimizing supply chains with just-in-time production using tools like SAP to personalizing customer interactions with a CRM, data provides crucial insights for efficiency and growth. Real-time data visibility allows businesses to identify potential bottlenecks, anticipate market changes, and improve resource allocation. This data-driven approach is crucial for proactive decision-making and maintaining a competitive advantage.

The Power of Connection and Collaboration

Breaking down data silos and fostering collaboration across departments and with external partners is paramount. Integrated software platforms connect various systems and stakeholders, ensuring smooth communication and data sharing. This connectivity promotes transparency and faster decision-making, enabling organizations to respond quickly to market shifts and customer needs. Strategic partnerships can provide access to valuable expertise and resources, accelerating digital transformation initiatives.

Navigating the Build vs. Buy Decision

Implementing new technologies requires careful consideration of building in-house solutions versus purchasing existing ones. Building solutions offers greater control but can be expensive and time-consuming. Buying solutions is often faster and more affordable but may not fully align with specific business needs. A strategic evaluation of resources, technical capabilities, and long-term goals is essential for making the optimal choice.

Empowering Your Workforce

Modern factories and digital processes demand a skilled workforce. Upskilling current employees and attracting new talent with digital expertise is critical. Training programs focused on software development, data analytics, and automation technologies equip the workforce for the demands of this digital era. Fostering a culture of continuous learning empowers employees to embrace new technologies and contribute to successful digital transformation.

Managing Risk in a Changing Market

Digital transformation involves inherent risks, such as market fluctuations, technological disruptions, and cybersecurity threats. A robust risk management framework is vital for identifying vulnerabilities, assessing their potential impact, and creating mitigation strategies. Regular review and updates to this framework ensure preparedness for unforeseen challenges and minimize disruption.

Addressing Legacy Systems and Security

Integrating legacy systems with new technologies can be a significant hurdle. Investment in system upgrades and integration solutions may be required to eliminate data silos and enable seamless data flow. Increased connectivity demands stronger cybersecurity measures to protect sensitive data and systems from evolving threats. Investing in security infrastructure, such as firewalls, intrusion detection systems, and regular security audits, is paramount.

Focusing on the Customer Experience

Digital transformation is redefining the customer experience. From online car configurators to personalized service reminders, digital tools offer opportunities to create seamless, personalized interactions. Omnichannel strategies that blend online and offline experiences cater to individual preferences and build stronger customer relationships. Using data analytics to understand customer needs enables targeted marketing, predictive service, and proactive engagement, leading to improved customer loyalty and satisfaction.

Implementing a Phased Approach

A phased approach to digital transformation enables organizations to manage complexity and minimize disruptions. Beginning with pilot projects to test new technologies and processes provides valuable learnings and allows for adjustments before full-scale implementation. This incremental approach allows for controlled experimentation, reduces risk, and increases the likelihood of success.

Ready to begin your automotive digital transformation? Willowood Ventures empowers car dealerships with innovative strategies designed to increase foot traffic, appointments, and sales. Learn more about how Willowood Ventures can help your dealership.

Your Automotive Digital Transformation Expert FAQ

Essential answers about modernizing your dealership with cutting-edge digital strategies

Automotive digital transformation refers to the comprehensive integration of digital technologies across all aspects of dealership operations, from digital marketing and sales processes to inventory management and customer service. It's not necessarily about overhauling everything but rather identifying repetitive, manual tasks that can be streamlined with digital process automation tools.

This transformation is crucial for dealerships because it:

- Enhances Customer Experience: Modern buyers expect seamless online-to-offline experiences, from browsing inventory digitally to completing paperwork electronically

- Improves Operational Efficiency: Automating tasks like inventory management and HR processes reduces time-consuming manual work, allowing employees to focus on more impactful projects

- Drives Competitive Advantage: Bloomberg New Energy Finance expects EVs to account for 10% of all new car sales by 2025 and 58% by 2040, making digital capabilities essential for selling and servicing these vehicles

- Increases Revenue: Data-driven insights enable better decision-making, personalized marketing, and improved lead conversion rates

Automotive digital transformation enables dealerships to adapt to changing consumer behaviors, meet rising expectations, and remain competitive in an increasingly digital marketplace. Those who embrace this transformation position themselves for long-term success and growth.

Digital showrooms and virtual experiences revolutionize how dealerships connect with customers, offering numerous specific benefits for automotive digital transformation:

24/7 Accessibility: Unlike physical showrooms, digital platforms allow customers to explore inventory, customize vehicles, and even take virtual test drives at any time, dramatically expanding your reach beyond traditional business hours.

Enhanced Customer Engagement: The popularity of digital retailing is booming. Online vehicle retail, aftersales, and services are forecasted to continue to acquire market share, and the global revenue from online vehicle retail is expected to increase fivefold, from $120 billion in 2018 to $605 billion in 2025.

Cost Reduction: Digital showrooms reduce overhead costs associated with maintaining large physical spaces while enabling dealerships to showcase their entire inventory, including models not physically present on the lot.

Data Collection and Insights: Virtual experiences track customer behavior, preferences, and engagement patterns, providing valuable data for analytics and personalized follow-up strategies.

Geographic Expansion: Digital platforms eliminate geographical barriers, allowing dealerships to serve customers across wider regions without the need for multiple physical locations.

These digital tools complement traditional showroom experiences, creating an omnichannel approach that meets customers wherever they are in their buying journey.

A successful automotive digital transformation strategy requires several interconnected components working together to modernize dealership operations:

1. Customer Experience Platforms: Implement comprehensive CRM systems, online scheduling tools, and digital retailing solutions that create seamless customer journeys from initial research to post-purchase service.

2. Data Analytics and AI Integration: Companies in the automotive industry have been using robots on assembly lines to increase their productivity since the 1970s, but this is becoming more common. Factories use data from IoT and machine learning advanced algorithms to manage their production lines.

3. Digital Marketing Excellence: Develop robust SEO strategies, social media presence, and targeted advertising campaigns that reach customers where they spend their time online.

4. Connected Vehicle Technologies: Connected vehicles: integration of other software and hardware for better customer experience. For example, intelligent components that can identify the need for their maintenance and provide notifications in advance.

5. Employee Training and Culture: Upskilling the workforce will be vital. Automakers must invest in training programs to equip employees with the skills needed to navigate digital transformation.

6. Cybersecurity Infrastructure: Protect customer data and dealership systems with robust security measures as digital connectivity increases vulnerability to cyber threats.

Success in automotive digital transformation requires balancing technology adoption with human expertise, ensuring that digital tools enhance rather than replace the personal touch that customers value.

Automotive digital transformation is not a one-time project but an ongoing journey that requires strategic planning and phased implementation for optimal results:

Initial Phase (3-6 months): Begin with assessment and planning. I always advise clients to start small, get a few onerous processes automated successfully initially, and then scale. This phase involves evaluating current systems, setting goals, and implementing pilot projects.

Implementation Phase (12-18 months): Roll out core digital solutions across departments. This includes launching digital showrooms, implementing CRM systems, and establishing marketing automation processes.

Optimization Phase (Ongoing): When you start to reap the benefits of the pilot automated processes digital transformation often naturally follows. Each department within the organization wants and needs to work smarter.

Key Timeline Considerations:

- Quick wins can be achieved within 30-60 days through simple automation

- Major system integrations typically require 6-12 months

- Cultural transformation and full adoption often takes 18-24 months

- Continuous improvement and adaptation should be ongoing

The most successful dealerships view automotive digital transformation as a continuous evolution rather than a fixed-duration project, constantly adapting to new technologies and changing customer expectations.

The ROI from automotive digital transformation can be substantial when implemented strategically, with measurable improvements across multiple areas:

Revenue Growth: IT spending is increasing from $38B in 2015 to $168B in 2025 – a significant growth. Dealerships typically see 15-30% increases in lead conversion rates and 20-40% improvements in customer retention through digital initiatives.

Cost Reduction Benefits:

- 30-50% reduction in manual processing time through automation

- 25-35% decrease in marketing costs through targeted digital campaigns

- 40-60% improvement in inventory turnover with data-driven management

Operational Improvements: By taking a paper-based process that relied on human interaction to determine weld quality and moving it to a process that reads data directly from laser welders, this major automotive OEM was not only able to improve their quality but also reduce their cycle time.

Customer Lifetime Value: Digital transformation enhances customer experiences, leading to increased loyalty and repeat business. Connected services and personalized marketing can increase customer lifetime value by 25-45%.

Competitive Advantage: Early adopters of automotive trends gain market share from slower-moving competitors, with some dealerships reporting 30-50% increases in market share within their regions.

While initial investments in automotive digital transformation can be significant, most dealerships achieve positive ROI within 12-18 months and continue seeing compounding benefits over time.

Automotive digital transformation represents a fundamental shift from traditional dealership operations, transforming every aspect of how dealerships engage with customers and manage their business:

Customer Engagement Evolution:

- Traditional: Walk-in traffic, print advertising, cold calling

- Digital: Online lead generation, content marketing, AI-powered chatbots, and personalized email campaigns

Sales Process Transformation: Customers can explore vehicles on their own time and complete paperwork digitally. This contrasts sharply with traditional methods requiring multiple in-person visits and manual paperwork.

Inventory Management:

- Traditional: Manual tracking, periodic lot walks, paper-based systems

- Digital: Real-time inventory tracking, predictive analytics for stocking decisions, automated pricing optimization

Marketing Approach: Traditional methods rely on broad-reach tactics like newspaper ads and billboards. Digital transformation enables precise targeting, measurable campaigns, and real-time optimization based on performance data.

Service Department: The transition from hardware-centric to software-defined vehicles has redefined how automakers compete. SDVs enable vehicles to adapt through over-the-air updates, integrating new features and services long after the initial sale.

The key difference is that automotive digital transformation creates data-driven, customer-centric operations that adapt in real-time, while traditional methods rely on intuition and historical practices.

Data analytics serves as the backbone of successful automotive digital transformation, turning raw information into actionable insights that drive strategic decisions:

Customer Behavior Analysis: Real-time data and analytics provide insights to fine-tune production schedules, predict market trends, and deliver better customer experiences. Analytics tools track customer journeys, identifying drop-off points and optimization opportunities.

Predictive Analytics Applications:

- Forecast which vehicles will sell fastest based on market trends

- Predict service needs before customers experience problems

- Identify high-value leads most likely to convert

- Optimize pricing strategies based on demand patterns

Operational Intelligence: Dealership analytics monitor key performance indicators across departments, enabling managers to identify inefficiencies and implement improvements quickly.

Marketing ROI Measurement: Digital analytics precisely track campaign performance, cost per lead, and conversion rates, allowing for continuous optimization of marketing spend.

Supply Chain Optimization: IoT sensors and supply chain data platforms provide real-time visibility into parts moving through the ecosystem. This enables just-in-time inventory management and reduces carrying costs.

Successful automotive digital transformation leverages analytics not just for reporting past performance, but for predicting future trends and automating decision-making processes that improve efficiency and profitability.

Timing is absolutely critical for automotive digital transformation success, as the industry is experiencing rapid technological changes and shifting consumer expectations:

Market Urgency: As we enter 2025, automakers are navigating a rapidly shifting landscape shaped by technological innovation, electrification, and evolving consumer expectations. Dealerships that delay transformation risk losing market share to more agile competitors.

Strategic Timing Considerations:

- Immediate Action Areas: Customer-facing digital tools like online scheduling and digital retailing should be implemented immediately to meet current expectations

- Phased Rollouts: Backend systems and complex integrations can be timed during slower business periods to minimize disruption

- Market Alignment: Time EV infrastructure investments with local adoption rates and manufacturer product launches

First-Mover Advantages: Early adopters of automotive digital transformation gain valuable experience, establish market leadership, and build customer loyalty before competitors catch up.

Cost of Delay: With established automakers facing nimble startups in the mobility race, building new business should be a priority for auto executives. Each month of delay means lost opportunities and higher implementation costs as technology advances.

The optimal time to begin automotive digital transformation is now, with a strategic, phased approach that prioritizes high-impact, customer-facing improvements while building toward comprehensive transformation.

Automotive digital transformation revolutionizes marketing effectiveness through precision, measurability, and adaptability that traditional methods simply cannot match:

Precision Targeting: Unlike traditional broadcast advertising, digital transformation enables laser-focused targeting based on demographics, behaviors, and intent signals. Lead generation becomes highly efficient when you can identify and reach in-market shoppers actively researching vehicles.

Real-Time Measurement: Data-driven connectivity services and on-demand mobility could add up to $1.5 trillion to the automotive revenue pool by 2030. Every digital interaction is trackable, providing immediate feedback on campaign performance and ROI.

Cost Efficiency Advantages:

- Pay-per-click advertising ensures budget is spent only on engaged prospects

- Automated email campaigns reach thousands at minimal cost

- Social media enables organic reach without traditional media buying expenses

- Retargeting captures lost opportunities that traditional methods miss

Personalization at Scale: Digital transformation enables mass personalization, delivering unique messages to each customer based on their preferences and behavior, something impossible with traditional print or broadcast media.

Continuous Optimization: Digital campaigns can be adjusted in real-time based on performance data, while traditional campaigns are fixed once launched. This agility dramatically improves results over time.

The effectiveness of automotive digital transformation in marketing lies not just in reaching more people, but in reaching the right people with the right message at the right time.

Willowood Ventures is the premier choice for automotive digital transformation because of our proven track record, innovative strategies, and unmatched results. As America's #1 automotive marketing agency, we've helped thousands of dealerships achieve record-breaking success through comprehensive digital transformation initiatives.

Our Proven Results:

- 300% Average ROI: Our clients typically see a 300% return on their digital transformation investments within the first year

- 85% Lead Conversion Improvement: Our integrated digital strategies increase qualified lead generation and conversion rates

- 50% Cost Reduction: Streamlined processes and automation reduce operational costs by half

- 24-Hour Response Time: Our dedicated support team ensures your transformation stays on track

Comprehensive Digital Solutions: From Facebook Sales Events that generate immediate traffic to long-term strategic marketing solutions, we provide end-to-end transformation services tailored to your dealership's unique needs.

Industry-Leading Expertise: Our team combines decades of automotive experience with cutting-edge digital expertise, understanding both the traditional dealership model and the future of automotive retail.

Guaranteed Performance: We're so confident in our automotive digital transformation strategies that we guarantee measurable improvements in lead generation, customer satisfaction, and overall profitability.

Choose Willowood Ventures to transform your dealership into a digital powerhouse that dominates your market and exceeds customer expectations.

Ready to Transform Your Dealership's Success?

Partner with Willowood Ventures, America's #1 automotive marketing agency. Our proven digital transformation strategies have helped thousands of dealerships increase sales, improve efficiency, and dominate their markets. Don't let your competition leave you behind in the digital revolution.